Page 11 - Annual report 2018 of the Böllhoff Group

P. 11

Innovation and developments

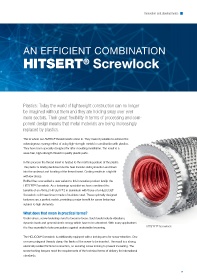

AN EFFICIENT COMBINATION

®

HITSERT Screwlock

Plastics: Today the world of lightweight construction can no longer

be imagined without them and they are holding sway over ever

more sectors. Their great flexibility in terms of processing and com-

ponent design means that metal materials are being increasingly

replaced by plastics.

®

This is where our AMTEC thread inserts come in. They make it possible to achieve the

advantageous synergy effect of using high-strength metals in combination with plastics.

They have been specially designed for after-moulding installation. The result is a

wear-free, high-strength thread in quality plastic parts.

In this process the thread insert is heated to the melt temperature of the plastic.

The plastic is briefly plasticised via the heat transfer during insertion and flows

into the undercut and knurling of the thread insert. Cooling results in a tight fit

with low stress.

Böllhoff has now added a new variant to this innovative product family: the

HITSERT Screwlock. As a fastenings specialist we have combined the

®

®

benefits of an AMTEC HITSERT 2 in aluminium with those of a HELICOIL

®

Screwlock coil thread insert made of stainless steel. These optimally designed

fasteners are a perfect match, providing a major benefit for screw fastenings

subject to high demands.

What does that mean in practical terms?

Under stress, screw fastenings tend to become loose. Such loads include vibrations,

dynamic loads and general kinetic energy which have to be absorbed. With many applications

HITSERT Screwlock

®

it is thus essential to take precautions against undesirable loosening.

The HELICOIL Screwlock is additionally equipped with a locking area for screw retention. One

®

or more polygonal threads clamp the flanks of the screw to be inserted. The result is a strong,

elastically resilient frictional connection, so ensuring screw locking to prevent loosening. The

screw-locking torques meet the requirements of the technical terms of delivery for international

standards.

7